ProSpray 3.20 - make your work easier.

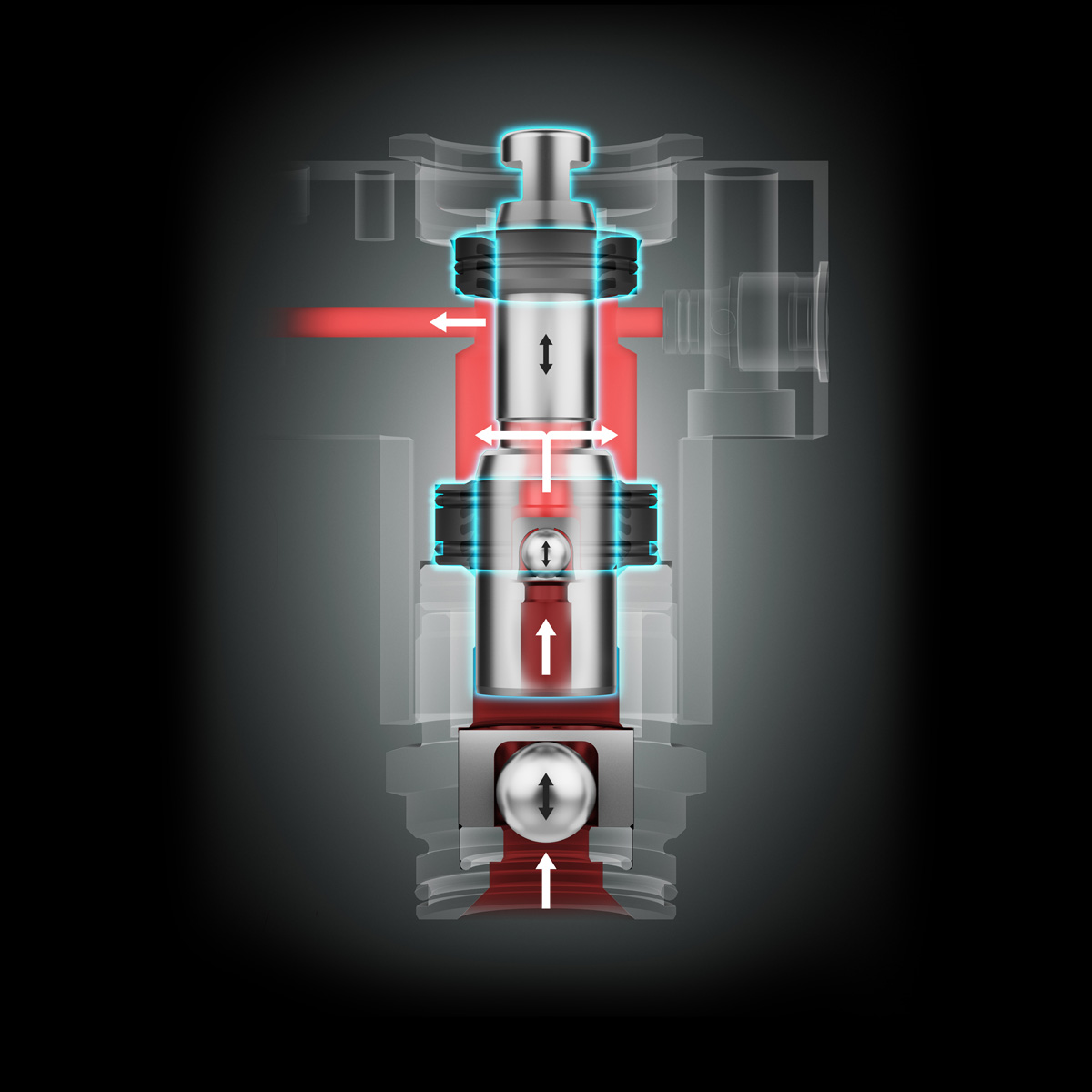

The ProSpray 3.20 is a tried-and-tested piston pump that WAGNER offers for professionals wanting to explore the advantages of airless spraying technology. Efficient and professional.

The ProSpray 3.20 airless entry-level device is part of the robust ProSpray range. The tried-and-tested piston pump technology features ideal material delivery and low wear. The compact construction of the PS 3.20 ensures excellent, fatigue-free operation on project sites. Ideal applications include medium-sized objects with materials such as interior emulsion paints. wood and metal paints can also be processed using a top hopper (5l). Profit from this modern technology and excellent value for money today. Professional. Profitable. ProSpray.