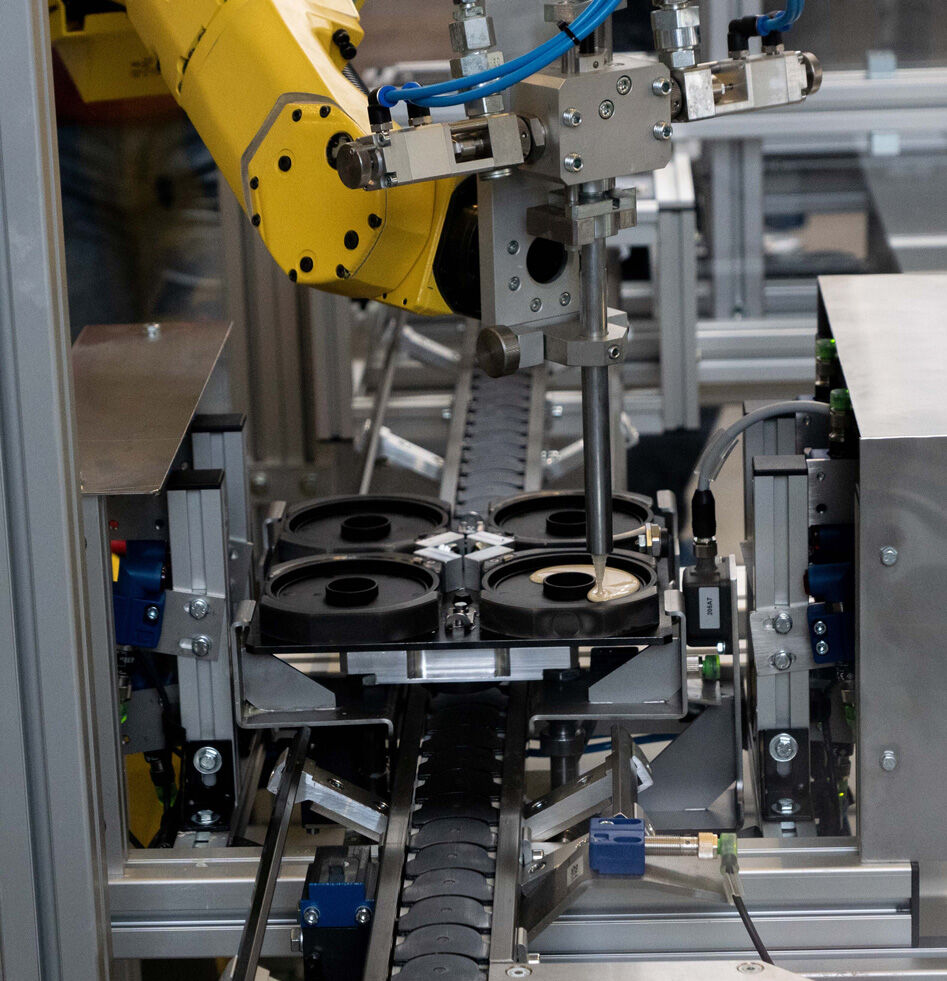

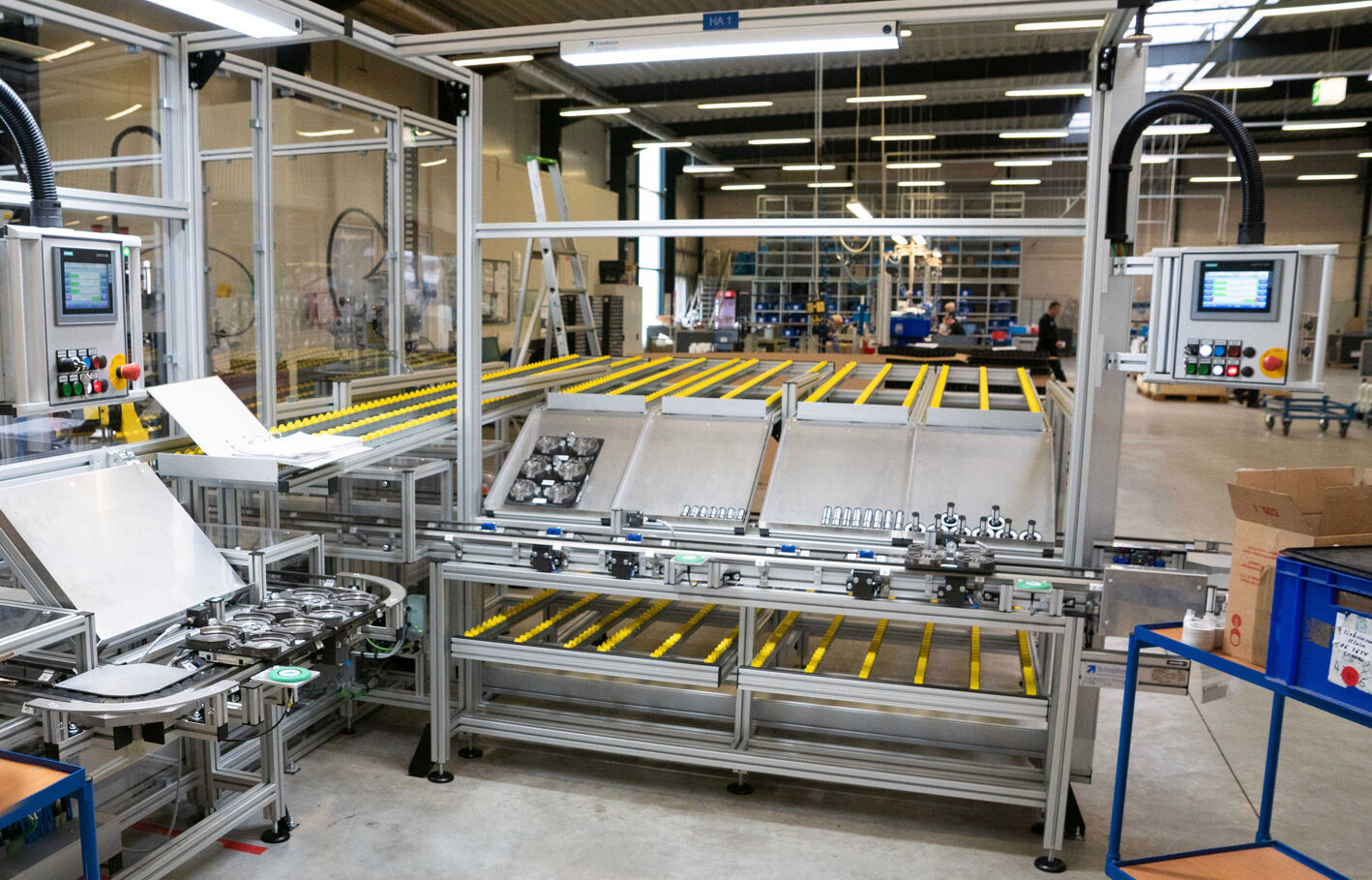

Automated adhesive dosing reduces unit costs

The success of a new fuel filter made it necessary for a well-known filter manufacturer in Germany to switch to automatic encapsulation. Reinhardt-Technik GmbH, a member of the WAGNER Group, had the solution with a complete automation cell including robot and modular 2K dosing technology.