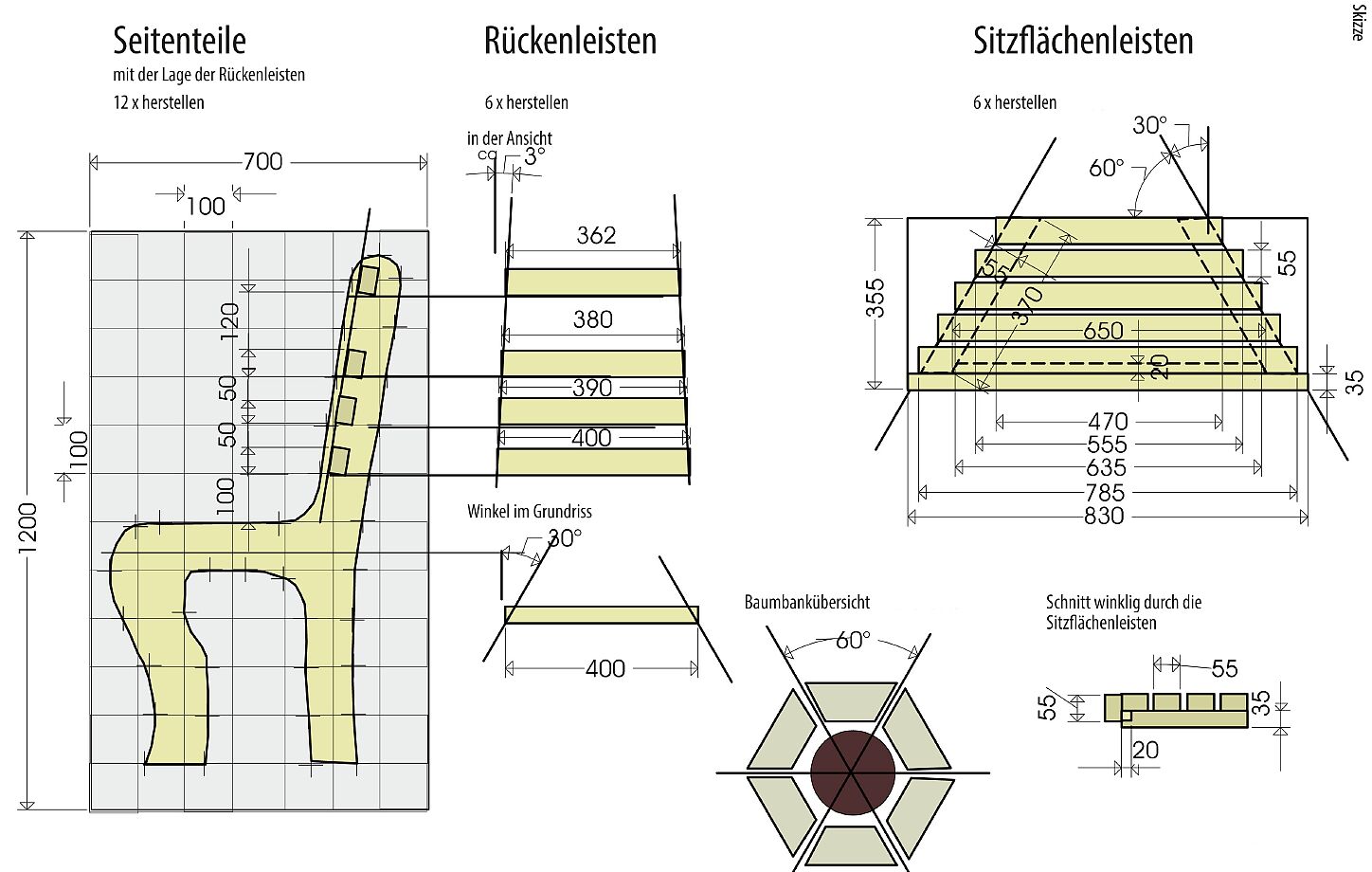

Instructions for a tree bench

In just a few steps, build a eye catching feature for your garden. With your tree bench, you can create not just a cosy seating area for you to spend quality time with your family and friends, but you can also create a truly decorative piece.