Optimizing production at Shoemaker: A story of efficiency and excellence

Shoemaker, headquartered in Cle Elum, Washington, has been a pioneering manufacturer of air diffusers and heating coils since 1947.

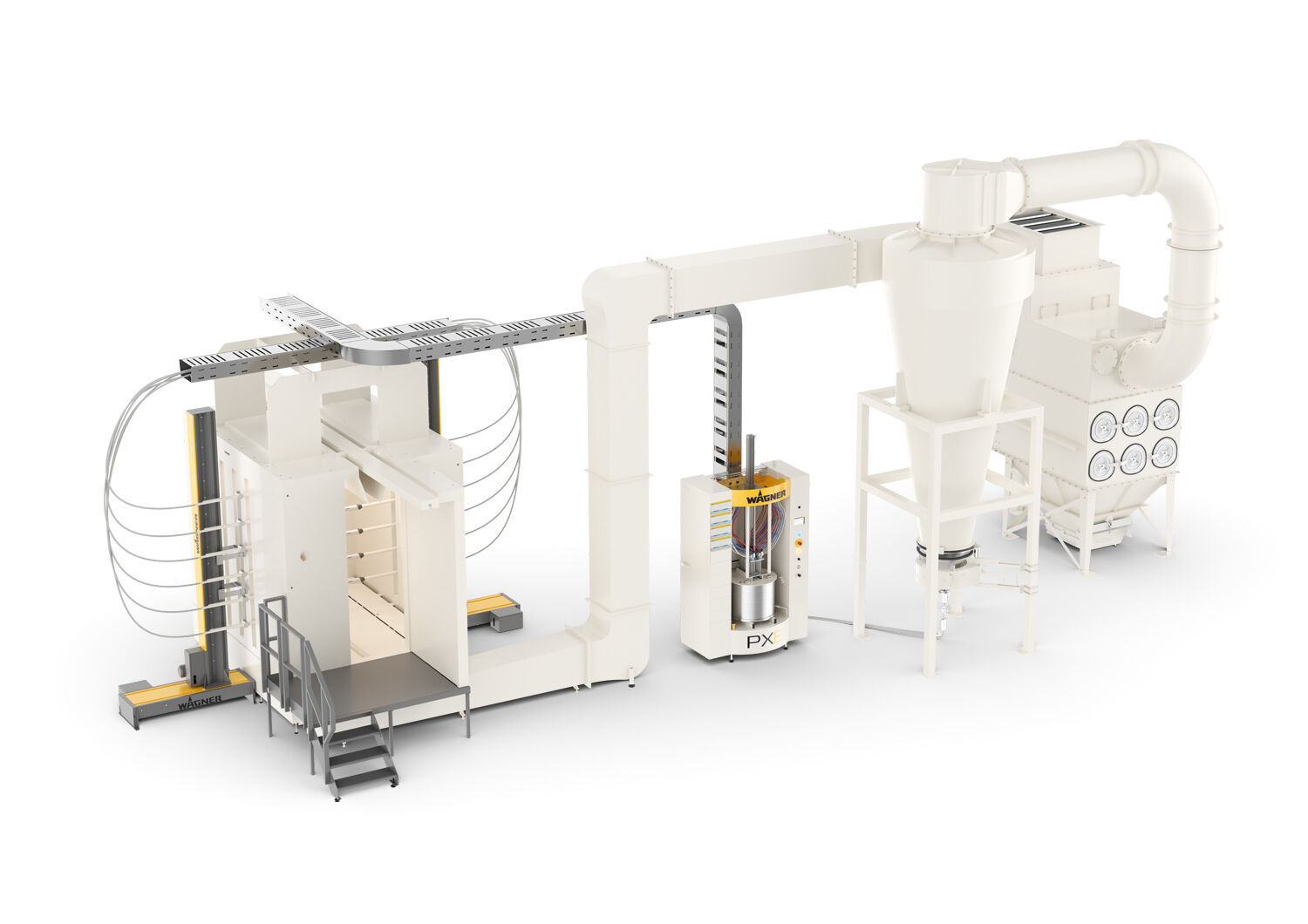

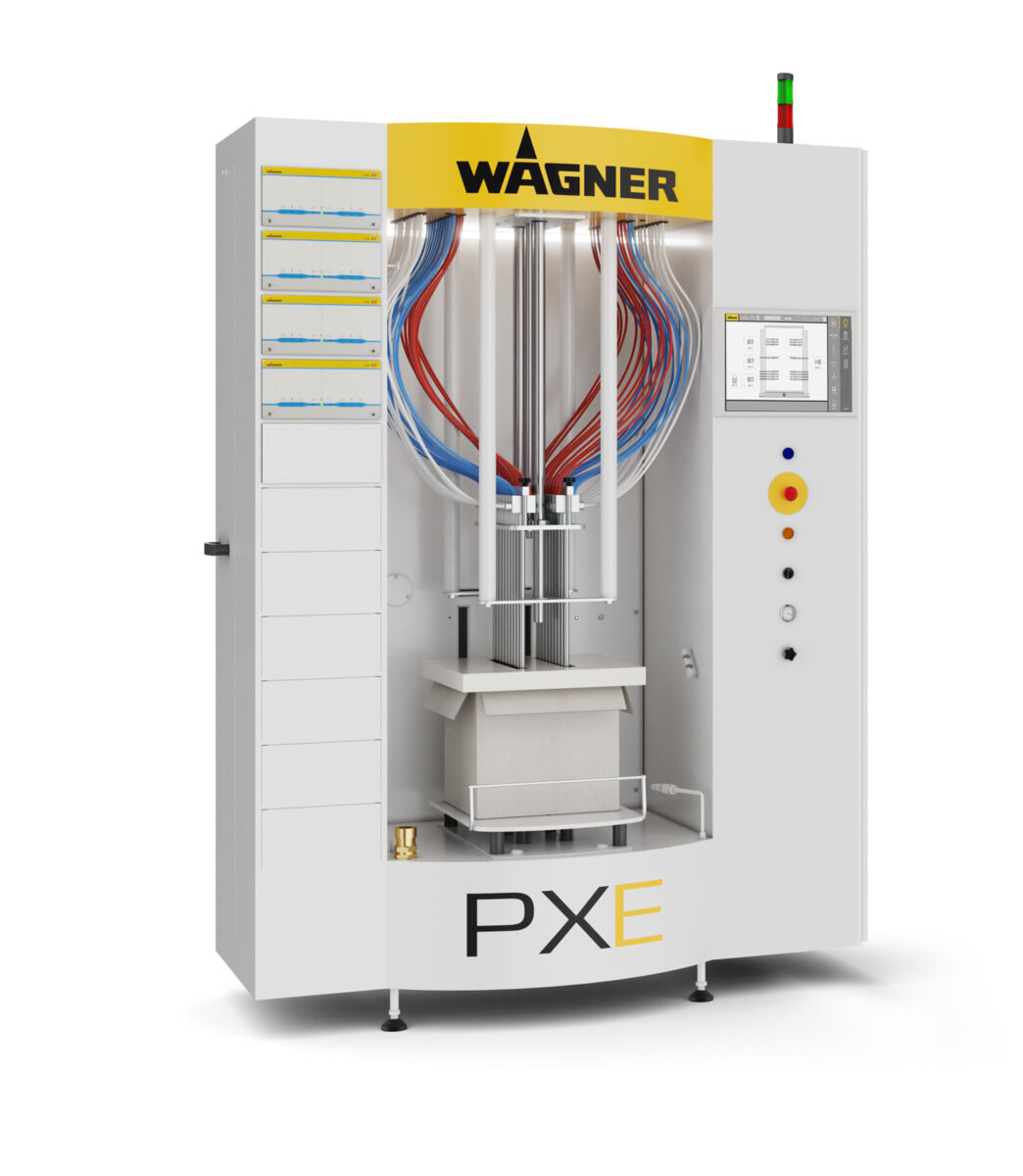

The company employs an advanced powder coating process to impart color to their intricate, multi-layered parts, fabricated from various metals. Initially, the coating process involved automatic booths for white and brown colors, while all other shades were applied manually. However, as the demand for non-white or non-brown components surged, Shoemaker encountered formidable challenges. Substantial manual involvement which resulted in potential variance in coating quality, depending on the operator's expertise, slowed down the production pace. Furthermore, inadequate powder extraction mechanisms undermined overall process efficiency.