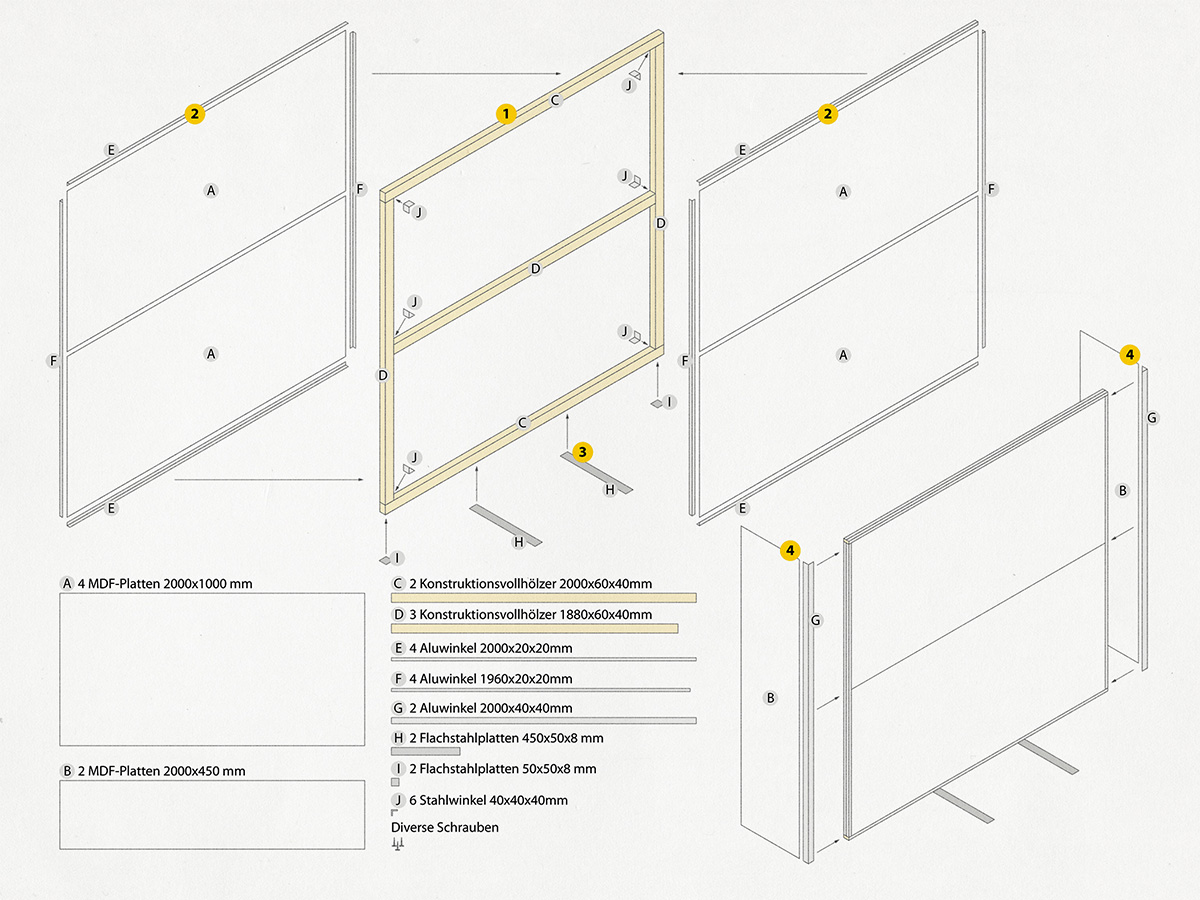

Building your own room divider sounds like a big and complicated endeavour. But it’s actually not hard at all! We've put together a step-by-step guide for you along with a detailed list of all the materials you’ll need. Then nothing can go wrong!

Kontakt

Language:

United Kingdom •

English

- Do-it-yourself Do-it-yourself

- Contractor Contractor

- Industry Industry

- Company

-

Contact

Language: United Kingdom • English