The SuperFinish 33 Pro and Plus are the most powerful diaphragm pumps WAGNER offers for the professional segment. Thanks to their unique QLS LongStroke technology, they can reliably handle a broad bandwidth of materials from low-viscosity paints and lacquers to highviscosity corrosion protections. The new family is based on the powerful and maintenancefriendly diaphragm pump technology for which WAGNER has been renowned for decades. The performance benefits: 20% performance increase over its predecessor model, three times longer service life for the inlet valves and less wear thanks to improved cooling.

Versatile in terms of applications and material

The new SuperFinish 33 family, with its 4.3 l/min delivery rate, works especially quickly and resiliently. This corresponds to a 20% performance increase over its predecessor. The effective QLS LongStroke technology, the only one of its kind on the market, ensures an optimised surface finish with greater intake performance and less wear. The longer stroke of the diaphragm allows a very wide range of materials to be processed for all kinds of applications and project sizes in both the residential and commercial sector. At the same time, the reduced stroke frequency is gentle on components, ensures quiet running and a long service life while at the same time keeping maintenance costs low. The replacement of common wear parts is straightforward and can therefore be carried out directly on site.

Efficient, fast and clean

Especially when painting, a low spray pressure creates a better spray pattern, controllable paint application and less overspray. Diaphragm pumps allow the variable control of pressure from 0 to 250 bar, while optimised atomisation is possible even at low pressure settings (30 to 40 bar). By using the innovative HEA nozzle technology, materials can be processed at low pressure and with up to 55 per cent less overspray. The separately available distributor adapter allows multi-gun operation with up to three guns.

Simple handling – high comfort

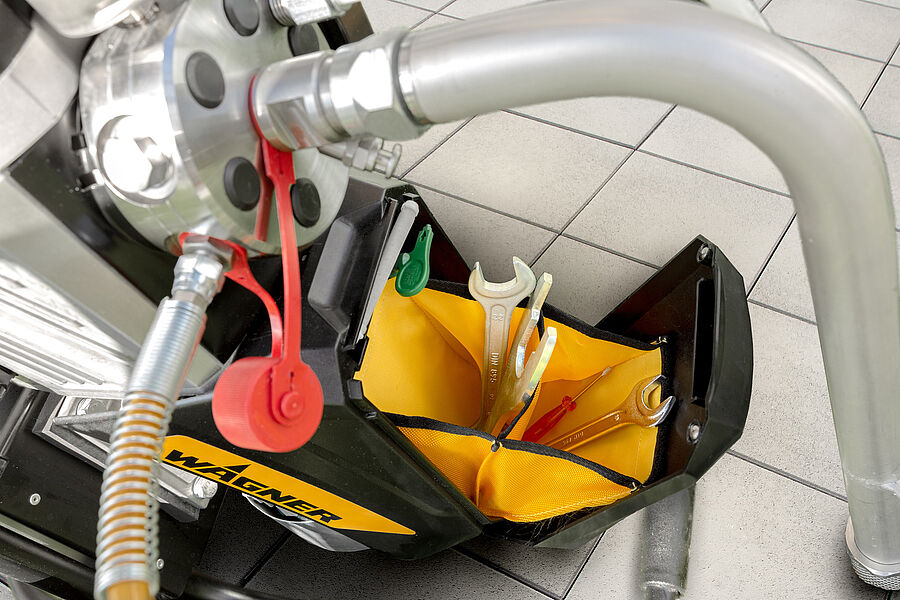

The user-friendliness of the SuperFinish 33 Pro and SuperFinish 33 Plus allows very quick familiarisation – even for employees without any in-depth technical expertise. This ensures that projects can be completed quickly, professionally and economically. An additional bonus is the integrated toolbox, which ensures that tips, filters and tools are always available. This saves time, money and the annoying task of searching for them.

User-friendliness Plus

While the Pro version boasts all of the features in the SuperFinish 33 family, the SuperFinish 33 Plus adds yet further value in terms of user-friendliness and safety. Its operation is simplicity itself with just a single, multi-functional switch, which controls the power to the pump as well as the circulation and spray mode. This prevents accidental switching on or off while the system is under pressure. The illumination of the multi-functional switch indicates the power supply to the device and also increases safety during operation. With just one hand movement, the carriage can be switched from working with a hopper to a suction system. The integrated 230 V socket is an added extra for quickly and easily connecting other equipment or accessories.

Reasons to choose diaphragm pump technology

When it comes to handling a range of materials with just one device, diaphragm pumps are the ideal choice. They require virtually no maintenance and lead the way with up to 50 per cent lower maintenance costs compared to piston pumps. Diaphragm pumps also have up to 58 per cent less material in the system, which is why they are also suited to be used with even small amounts of material. Diaphragm technology also facilitates an extremely fine and even spray pattern. Compared to piston pumps, the diaphragm's shorter stroke reduces the pulsation, avoiding irregularities in the spray pattern. The QLS technology, with its optimised hydraulics and specialist valve technology, makes the processing of all kinds of materials possible. As a result, it is especially easy to also efficiently apply high-viscosity materials.

WAGNER professional guarantee

Every WAGNER spray device comes with a three-year manufacturer's guarantee. With online registration, this is extended by a further two years to five.

For more information visit: go.wagner-group.com/sf33