Functional coatings: Spray application with WAGNER equipment

Functional coatings typically aim to alter the surface functions as well as the properties of a component. Unlike decorative paint, where the primary concern is aesthetic preference, functional coatings are mostly applied for protective purposes. In this way, the surfaces are to be provided with new or improved propertiesdepending on the nature and requirements of the component or object. This includes, for example, improved wear protection or corrosion protection for increased longevity of the object. Surface protection against heat, weather or any other damaging influences is basically necessary for every building, every system and almost every object in one way or another.

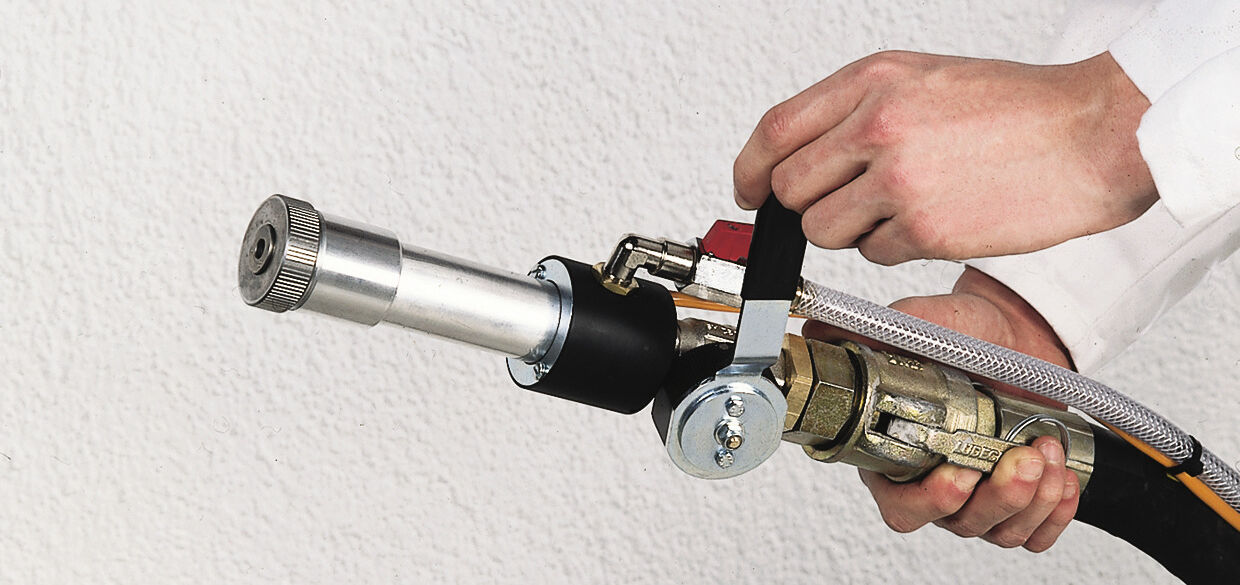

We provide insights into surface protection with functional coatings - applied with various WAGNER professional spray equipment.