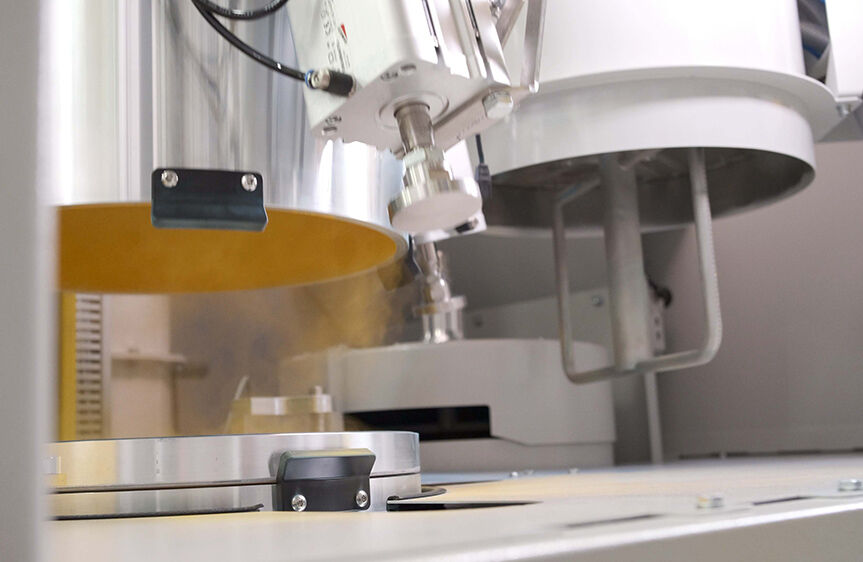

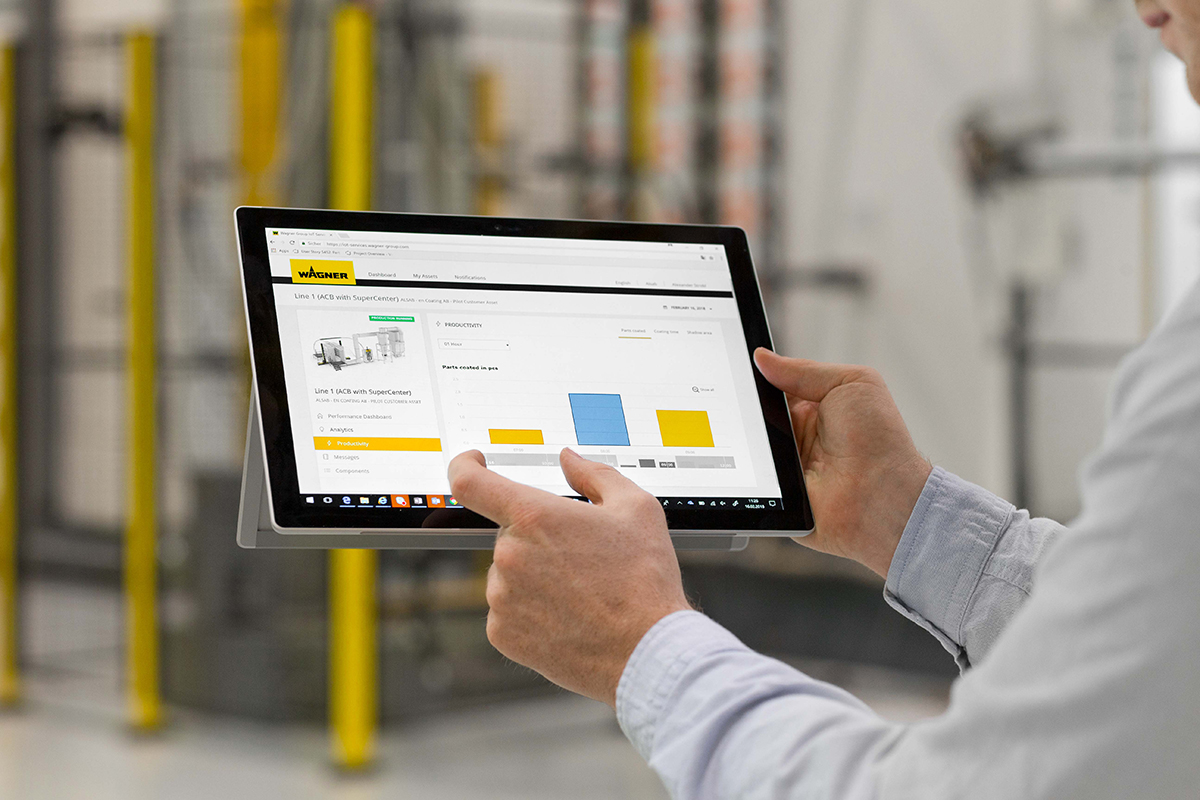

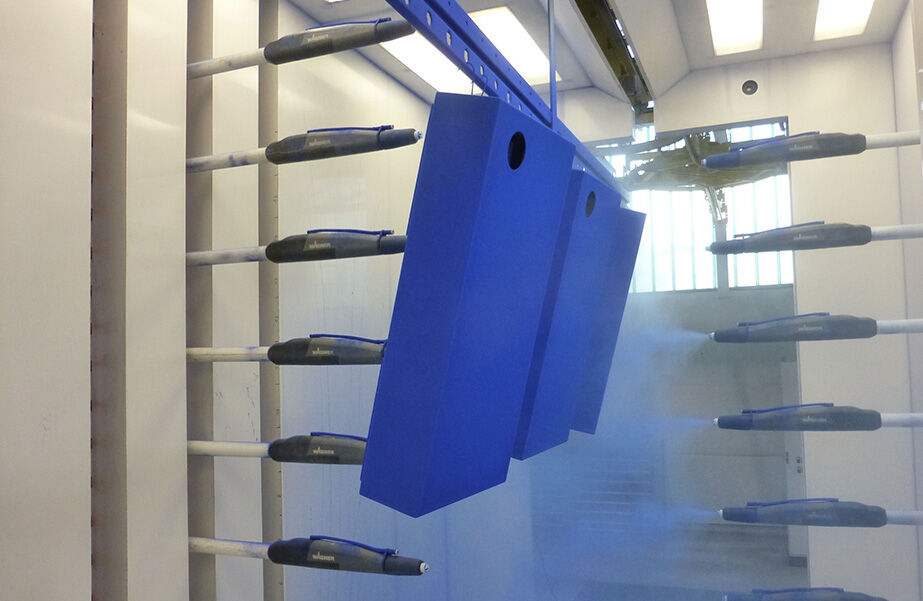

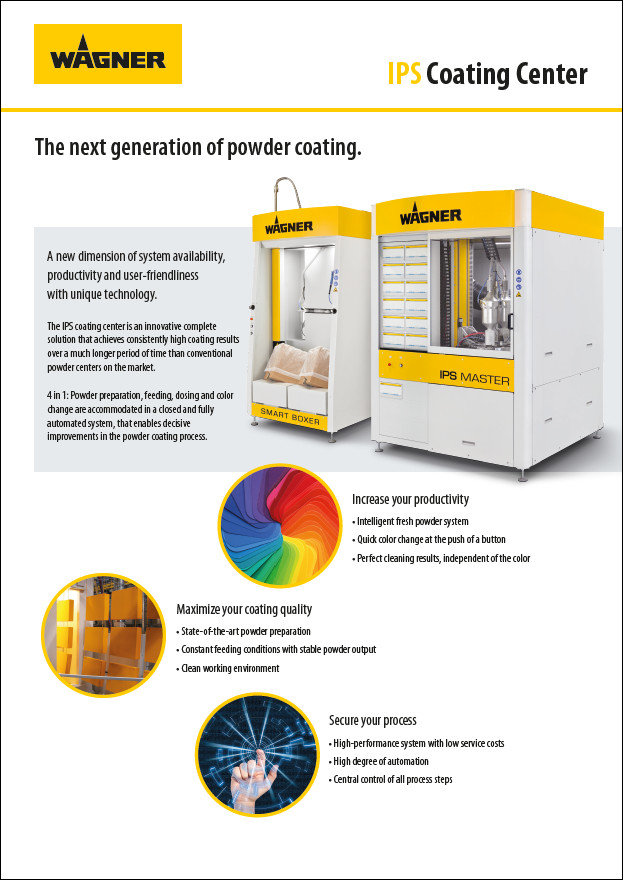

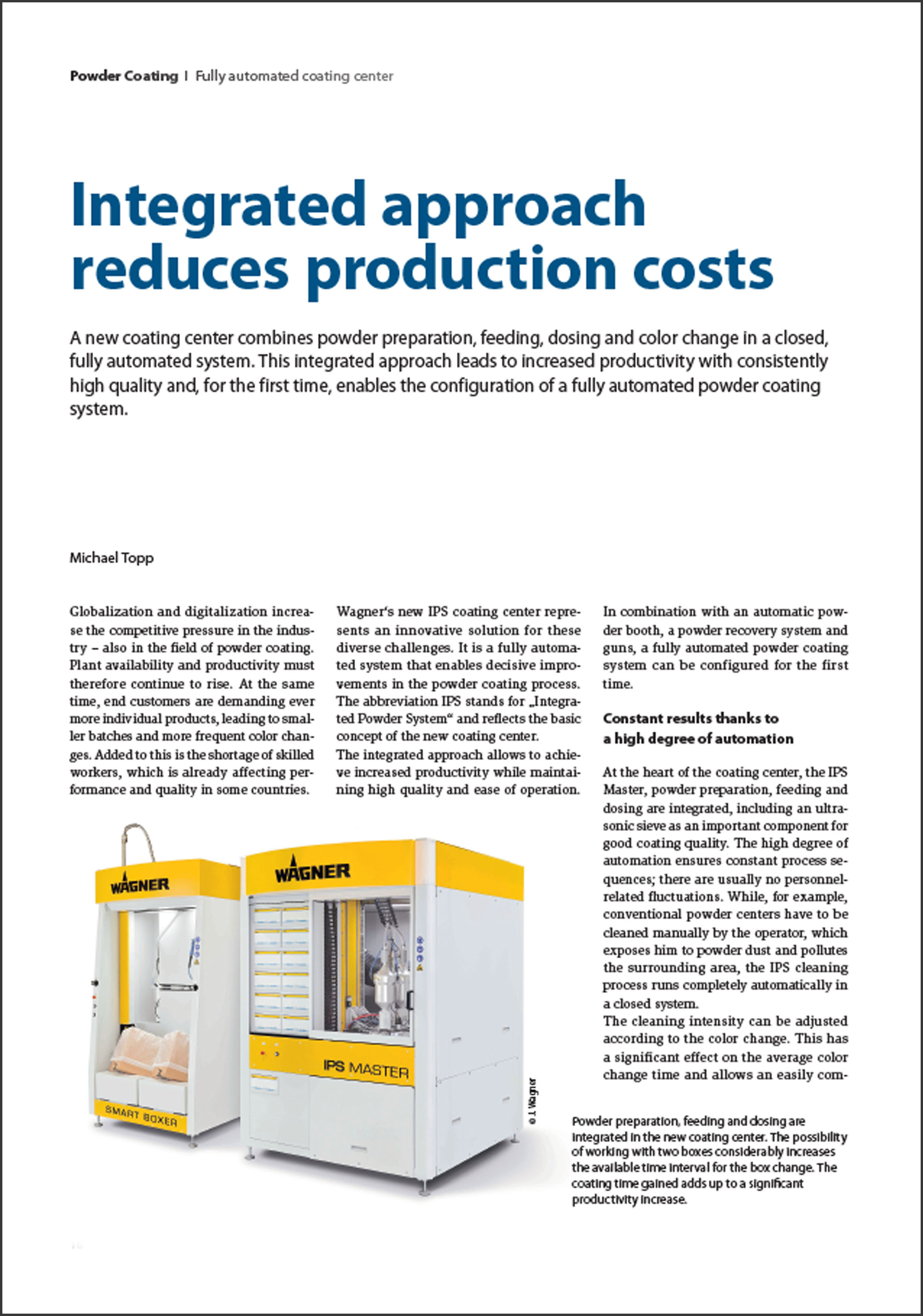

The IPS coating center is an innovative complete solution that achieves consistently high coating results over a much longer period of time than conventional powder centers on the market.

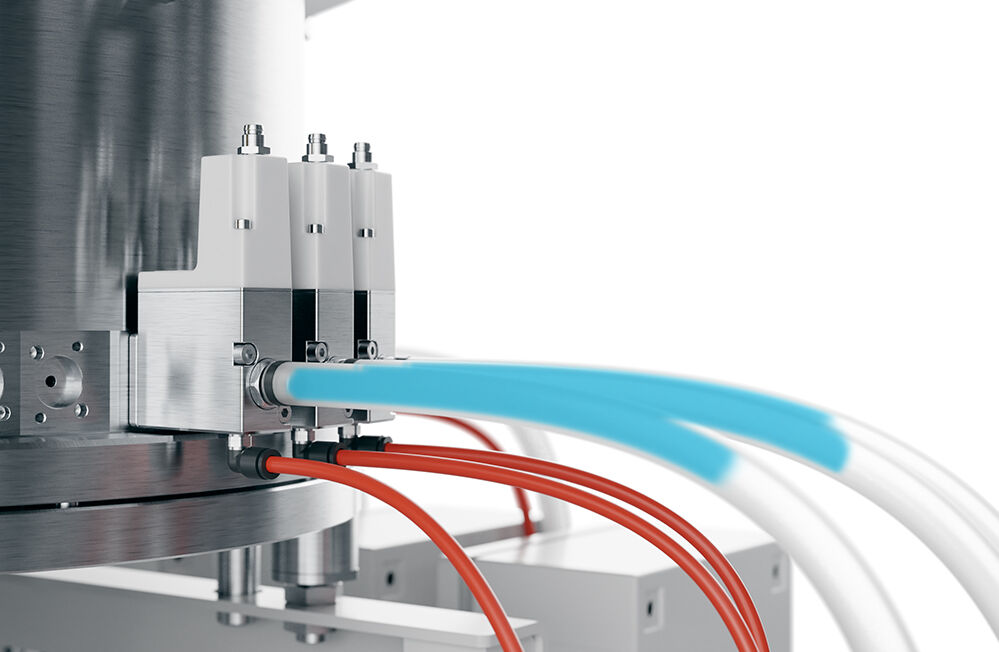

4 in 1: Powder preparation, feeding, dosing and color change are accommodated in a closed and fully automated system, that enables decisive improvements in the powder coating process.