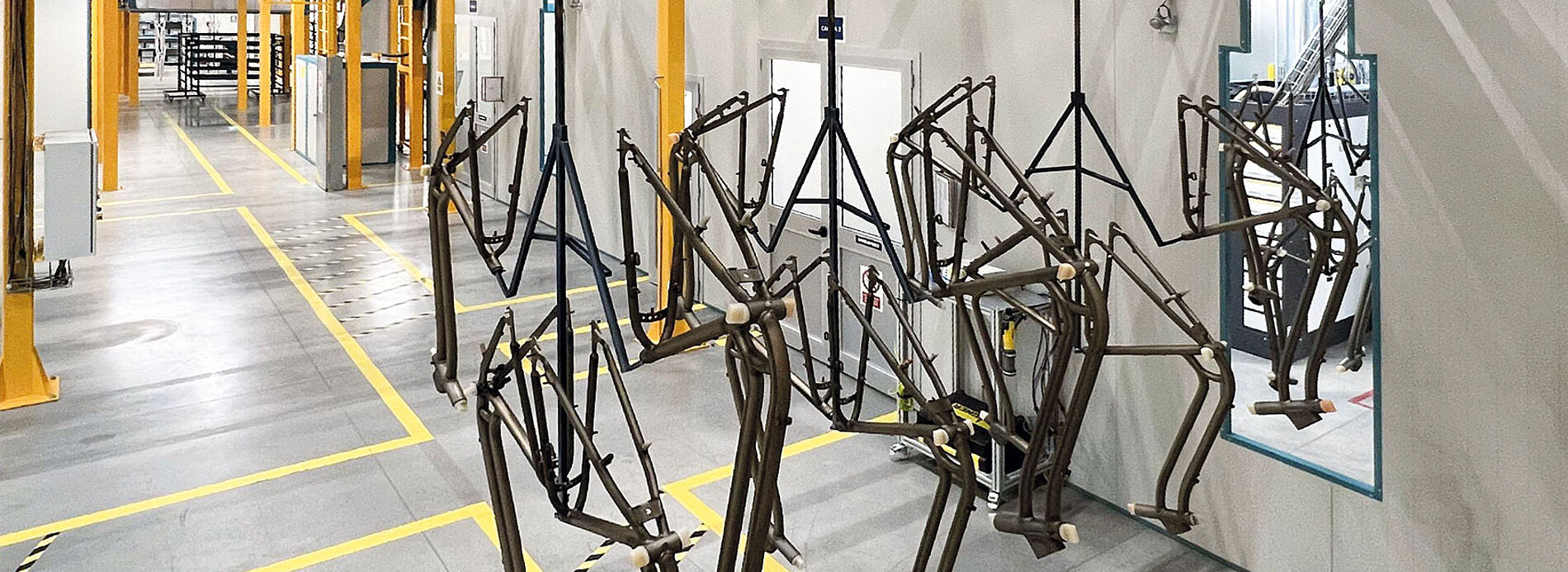

New powder coating plant in Europe's largest bicycle factory

In 2021, the bicycle manufacturer Sport Mechanical Workshop (SMW) opened a new factory in Romania in cooperation with the French sporting goods retailer Decathlon. With approximately 25,000 m2, this is one of the largest of its kind in Europe, where up to 2 million bicycles are to be produced and coated annually. For the powder coating process, SMW was looking for a flexible solution with high productivity to meet such high volumes and individual requirements for the bicycle design. The coating technology (booths, powder center, application) comes from WAGNER.