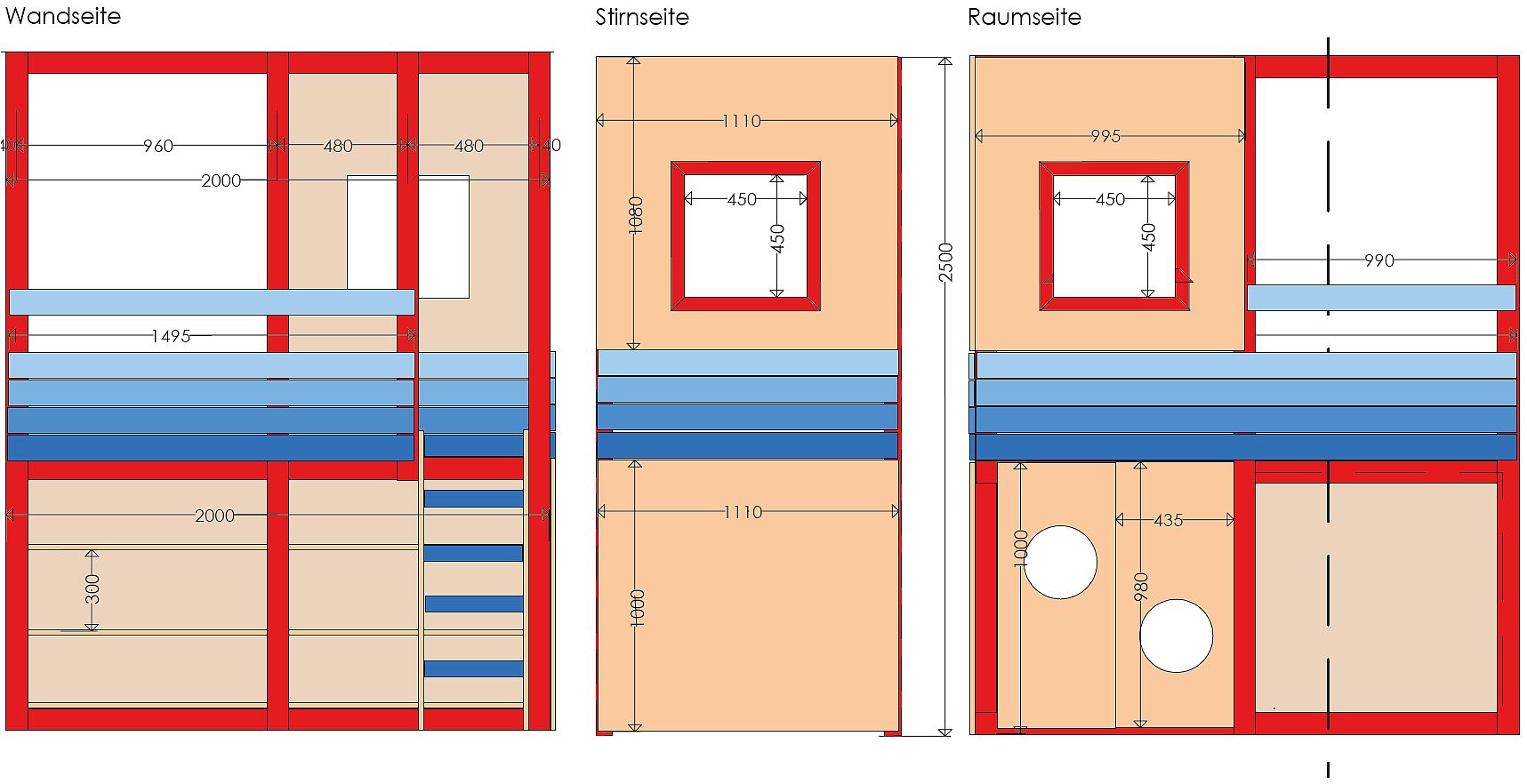

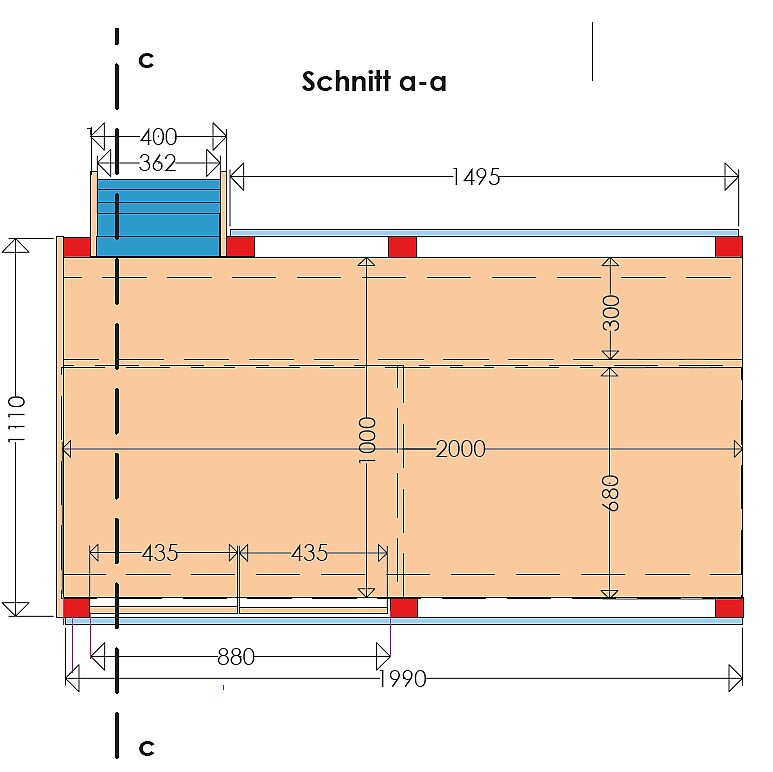

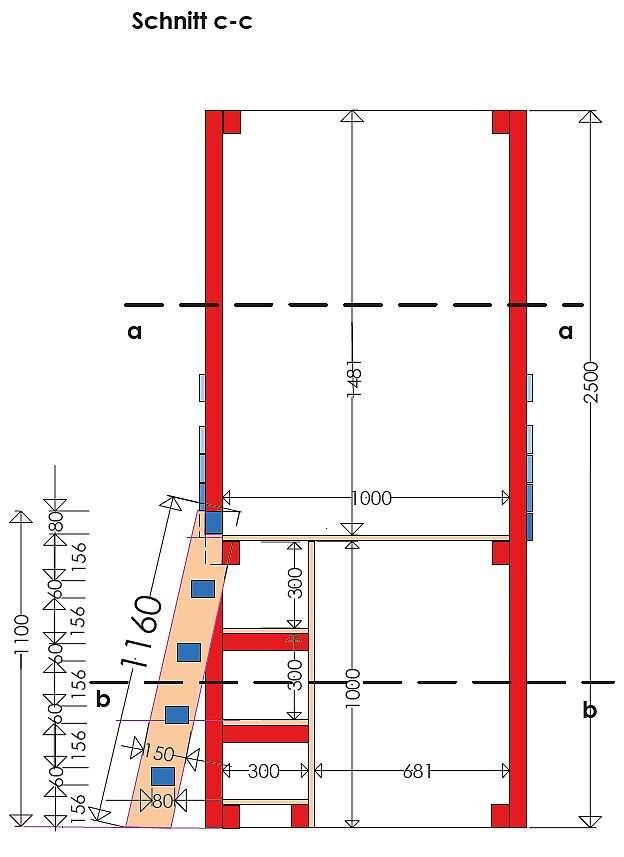

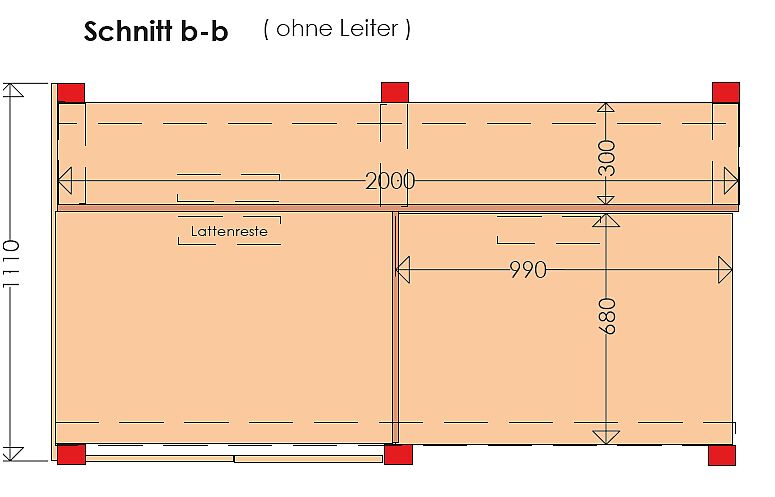

Guide to building a children's bunk bed

What child has not dreamt of this - his or her very own loft bed. From sleeping to playing or climbing - this guide shows you how to very quickly turn this dream into reality for your child. As well as looking good, loft beds are also extremely practical. The space under the bed surface can be used for playing or snuggling up and it also provides extra storage space for toys, bed linen and much more.